R&D Success: High-Performance Lightweight Convinces in Mechanical Engineering

For Burckhardt Compression AG, the Winterthur-based compressor manufacturer and world market leader in the field of compressor systems, CrossTEQ AG is realizing a geometrically complex valve plate with high-performance material properties using its own x-NET precision compression molding process.

Customer Success Story: Significantly improved efficiency of large reciprocating compressors due to ultra-light and resistant valve plate

Customer: Burckhardt Compression AG

Industry: Mechanical engineering, reciprocating compressor systems

Material: Chopped tapes made of thermoplastic carbon fiber, PEEK/CF

Technology: x-NET Precision Compression Molding

USP: Temperature & pressure resistance

The high-quality fiber composite material gives the valve plate reliable and durable properties under the most adverse pressure and temperature conditions.

- Temperature resistant

- Strong & pressure resistant

- Lightweight

- Precise contour; Minimal reworking

- Cost-effective from medium series size upwards

With high strength and low weight, valve plate life and compressor efficiency are significantly improved.

When our material reaches its limits, we rely on CrossTEQ's high-performance composites.

- Luzi Valär, Vice President Research & Development at Burckhardt Compression AG

Why thermoplastic composites in mechanical engineering?

Thermoplastic fiber composites combine the best material properties of metals and plastics and convince with high performance in mechanical systems and subsystems under the most adverse conditions:

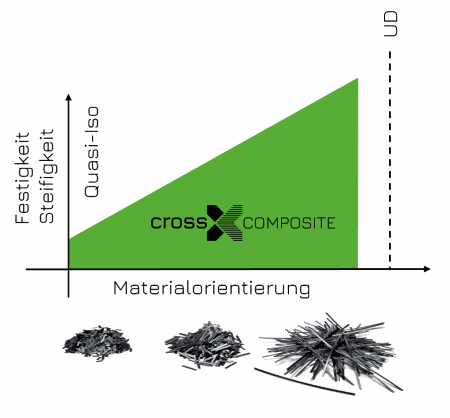

- High performance thanks to the realization of load paths

Application-oriented production processes (e.g. Cross Composite Technologies from CrossTEQ) enable the realization of load paths and thus the targeted use of strength and stiffness.

- Long service life under the most adverse conditions

Thanks to their outstanding properties, thermoplastic fiber composites outlast even the harshest pressure and temperature conditions. - Scalable process solutions

Application-specific composite compression molding technologies enable automated, cost-optimized mass production of simple to geometrically complex features and 3D structures. - Cost-efficient even from small series sizes

The high degree of automation in the thermoplastic compression molding process and the high level of functional integration reduce the number of components, and thus the production costs, to an optimum.

About x-NET Precision Compression Molding

X-NET Precision Compression Molding is a proprietary composite production technology from CrossTEQ based on an advanced precision molding process for carbon parts originally developed for aerospace applications.

With x-NET, we produce high-quality, contour-accurate composite parts with the highest level of functional integration and 0% material waste. Learn more.

Votre contact