About us

Tool-Temp products are used in all processing industries: plastics, die casting, injection moulding, extrusion, rubber, silicone, chemical, pharmaceutical, food, printing, lamination, textile and more.

Produkte:

- Universal water and oil temperature control units

- Water temperature control units

- Pressurised water temperature control units

- Oil temperature control units

- Cooling units and cooling systems

Sophisticated temperature control units and cooling systems from Tool-Temp

Temperature control units can be categorised into two groups based on the medium used. Temperature control units for operation with water have a maximum working temperature of 90°C for open tank designs and 160°C for pressurised water systems, depending on the design.

If oil is used as the medium, a maximum working temperature of 360°C can be achieved. In addition to the temperature control medium, the heating and cooling units can also be divided into two groups on the basis of their cooling system. A distinction is made between directly and indirectly cooled units.

Tool-Temp offers universal temperature control units with water at 90°C, or oil at 150°C, pure water units up to 90°C, pressurised water temperature control units with closed circuit up to 160°C, oil temperature control units 360°C and cooling units from -25°C to +40°C.

In addition to advice on product selection, Tool-Temp supports you in all your concerns. In particular, also in the maintenance of your production plants through a comprehensive service and maintenance offer. The customer service relieves you of work, ensures trouble-free production operation and increases the overall service life of your production plant.

Tool-Temp temperature control units in plastics

The use of temperature control units can increase process stability in injection moulding and improve productivity. Temperature control units increase product quality, optimise cycle times and guarantee consistent dimensional accuracy of the products. Temperature control units have become indispensable for engineering plastics. A more cost-efficient result is achieved in every case.

Advantages of Tool-Temp temperature control units in plastics

- Increased process stability

- Optimum surface finish

- Temperature measurement accurate to a tenth of a degree

- Short response times for customised solutions

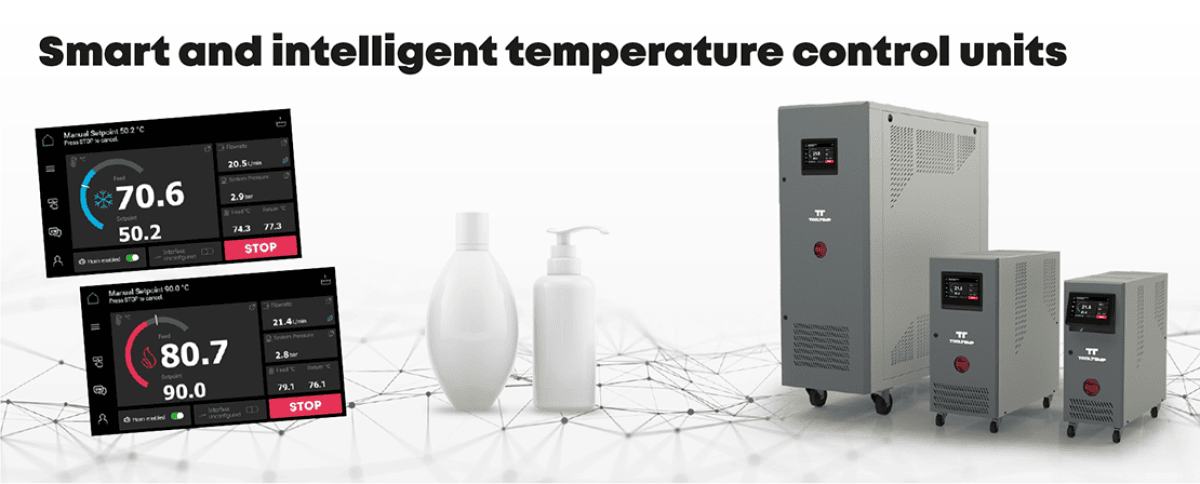

Tool-Temp will present the new smart and intelligent temperature control units of the MATIC product line at Swisstplastics 2023.

At Swissplastics, Tool-Temp AG will present the first temperature control units of the new MATIC product line for the first time on the Swiss market.

Temperature control has a major influence on product quality, productivity, energy efficiency and production costs. Based on these requirements, Tool-Temp has developed the MATIC line of equipment and the associated IRIS controller. The units are characterised by their ease of operation and a predictive control system that adapts automatically to the circumstances.

With the new IRIS controller, Tool-Temp offers a smart and intelligent solution for all types of process temperature control. The user can expect simple handling and, at the same time, a state-of-the-art communication and interface solution that is geared towards the future.

All operating data such as temperatures, pressures, flow rates, operating states, status messages, diagram data and data histories are available in the controller. IRIS continuously informs, reports and optimises the operation of the temperature control unit.

In addition to local operation on the touch screen, remote access is possible. Using a terminal device such as a telephone, tablet or PC, you can access the web server integrated in the temperature controller via a web browser. The connection is made via LAN cable or via the WLAN adapter integrated in the controller. The operation does not differ in any way from manual operation.

The model-based algorithms continuously summarise all available data and compare it with the current, expected behaviour. This constant adaptation enables the overall system to guarantee optimal, uninterrupted and reliable temperature and flow control and reliable monitoring of the process.

The main features of the MATIC temperature control units:

- Simple operation

- Modular and easy to expand

- Predefined actions and easily configurable recipes

- Predictive behaviour & predictive maintenance

- Connectivity - OPC-UA

- Energy-efficient and ecological