Increase bulk density and improve flowability

The trend towards ever lighter and thinner PET packaging, which has continued for several years, has a direct impact on the production process of many companies. This article shows you how to solve problems with low bulk densities or pourability effectively.

Problem:

The trend towards ever thinner PET packaging has a direct influence on the production process. The production waste fed into the recycling process, such as punched grids and purchased recycled flakes, have ever lower bulk densities.

This leads to new challenges for plastics processors in material handling and dosing, especially when single-screw extruders are used, as the machines are often not designed precisely for this material specification:

- The throughput capacity of the extruders is reduced by up to 50% due to the low bulk density.

- The flowability is often insufficient due to the grain shape, which leads to additional disturbances due to bridging during material feed

- The specific energy consumption increases

Only the latest extruders with twin screws or compressor screws specially designed for the material are equipped for the new flake qualities. Investments in new twin-screw extruders amount to up to EUR 2.2 million.

The bulk density can also lead to a problem with upstream processes such as drying, crystallization or decontamination, and the respective reactor output can drop due to volume limitation.

Solution approach:

Due to the above-mentioned problems, the use of a Herbold Plastkompaktor is an attractive economic alternative, especially for optimizing existing extruder lines.

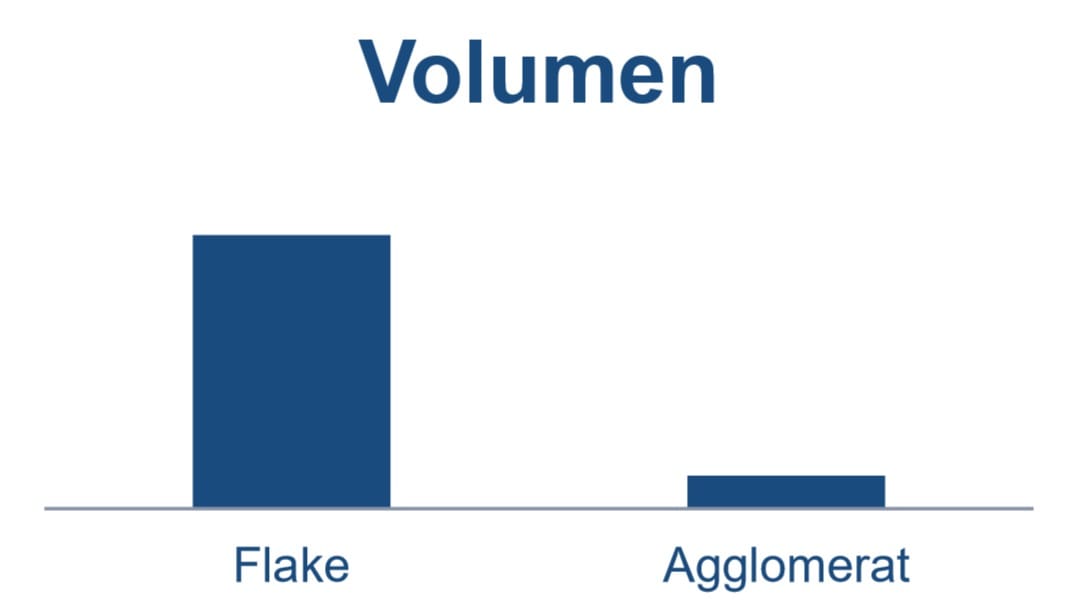

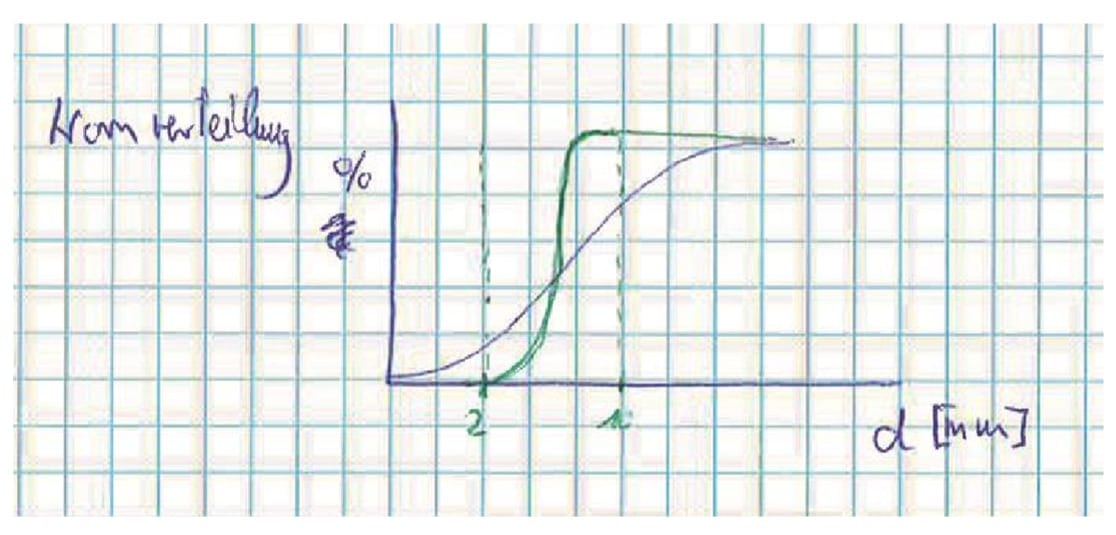

Bulk density and flowability can be ideally improved with the Herbold Plastkompaktor. Both the bulk density is increased, and the flowability decisively improved. This results from the change in grain shape from a flat to a grain-shaped agglomerate with a grain size range of about 2-10 mm.

The following table shows the results of other materials:

| Material | Input bulk density | Output bulk density | |

| PET plastic flakes | 60 g/l | 550 g/l | 9.1 times increase in bulk density |

| A-PET | 440 g/l | 470 g/l | 6 % increase in bulk density, but at the same time significantly improved flowability |

| A-PET | 220 g/l | 492 g/hl | 2.2 times increase in bulk density |

| A-PET | 480 g/l | 476 g/l | The input material was very thick and flat; therefore the bulk density does not increase in this case, but the flowability is considerably higher due to the defined smaller grain size of the agglomerate. |

The plastic compactor can be operated both in-line and off-line with the extruder. In the in-line circuit, the material is heated during compacting and subsequent shredding and can also be used in the extruder. This further improves the energy balance.

Customer benefit:

- The throughput capacity of the extruders can be maximized again.

- The specific energy consumption at the extruder drops.

- The improved flowability of the agglomerate increases process reliability and minimizes the risk of bridging.

- The operating costs and throughput of reactor processes can also be optimized.

Your contact person