Service

Excellent support for first-class technology

In times of digitalisation, when more and more services are available remotely, HB-Therm offers numerous new possibilities for customers with the Series 6 and the Thermo-6 temperature control units - efficient, flexible and location-independent.

-

e-cockpit App for Android and iOS -

Knowledge Database -

Gate-6 - The gateway to the digital world

Digitalisation is an important aspect of customer cooperationDurability

HB-Therm's Thermo-6 temperature control units once again represent the industry benchmark in terms of durability and warranty on various components. In addition to the heater, the flow meters are now also among the components with a lifetime warranty on function and tightness. Those with a lifetime warranty on these major components no longer need to worry about failure or service.

Trend-setting technology

The selected hardware and software architecture in the Thermo-6 allows, for the first time, unrestricted and data-secure access to the digital world for all customers who want it. Process data recording, unit history, unit-specific documents such as certificates, calibration data, operating and installation instructions - all this can not only be displayed quickly and clearly, but can also be made available to HB-Therm's specialists as information to serve as a basis for additional information and actions. In addition, mobile access to and working with all relevant process data is also possible on any mobile device.

Highest data security

Anyone who talks about comprehensive digitalisation must also guarantee the highest data security standards. At HB-Therm, all customers are on the safe side here too. The highest security standards guarantee comprehensive data protection. For example, remote access or the uploading of analysis data only takes place after explicit approval by the customer.

The "gateway to the digital world" of HB-Therm

Gate-6 and "e-cockpit" are the concrete answers to today's needs and future challenges in the digitalisation of temperature control technology. Control, analysis and support - all this functions digitally from anywhere at the touch of a button. This includes, for example, sending analysis data, remote control of the temperature control units or remote access to the data of the Thermo-6. In this way, the specialists at HB-Therm can help all customers with the digitalisation of their production - making many things easier and faster. From problem solving to maintenance orders and spare parts supply.

Control becomes very easy: "e-cockpit".

With the "e-cockpit" application on the mobile smartphone, all Thermo 6 users can work even more efficiently and safely. Via "e-cockpit", analysis data can be called up, remote access is possible, all online documentation of the "Knowledge" platform can be accessed directly, or, for example, a unit-specific ticket can be created at the touch of a button. This gives customers a transparent overview of the current production process and allows them to intervene immediately, even remotely, if problems occur.

The app for smartphones and tablets accesses the Gate-6 interface server and the Thermo-6 units connected to it locally via Bluetooth. "e-cockpit" contains the scanner for the HB-Therm-specific QR codes on the unit. Up-to-date analysis data from a Thermo-6 can be sent to the "Ticket" at the touch of a button. In addition, "e-cockpit" allows remote access "Remote Support". This creates access to an HB-Therm representative via a secure connection so that the unit can be accessed directly if necessary. In the "e-cockpit" and in the "Ticket", unit-specific data such as spare parts lists and calibration certificates are also available. Other "e-cockpit" functions such as "Remote Access", which allows access to a Thermo-6 from another company location, or the "Remote Control" of a Thermo-6 via tablet or smartphone are also part of the free "e-cockpit" app in the Play Store.

Keep everything in view: Gate-6 interface server

The Thermo-6 communicates with the injection moulding machine's control system via Ethernet. This can be done either directly via OPC-UA or the Gate-6 interface server. Gate-6 is able to translate the Euromap 82.1 protocol into various manufacturer-specific machine protocols. These are:

- DIGITAL interface (ZD)

- CAN interface (ZC)

- PROFIBUS-DP interface (ZP)

One Gate-6 is required for each injection moulding machine, which is ideally permanently assigned to the machine. A specific name can be assigned to the Gate-6 for better identification, e.g. the internal machine designation and department. The Gate-6 can communicate with the "e-cockpit" app via Bluetooth or WiFi. This means that, for the first time on a temperature control unit series from HB-Therm, a clear and informative compilation of all important data and documents of the connected Thermo-6 is available. This connectivity allows to organise the units locally in order to always have an overview of all units in use. This function puts an end to the "eternal" search for temperature control units.

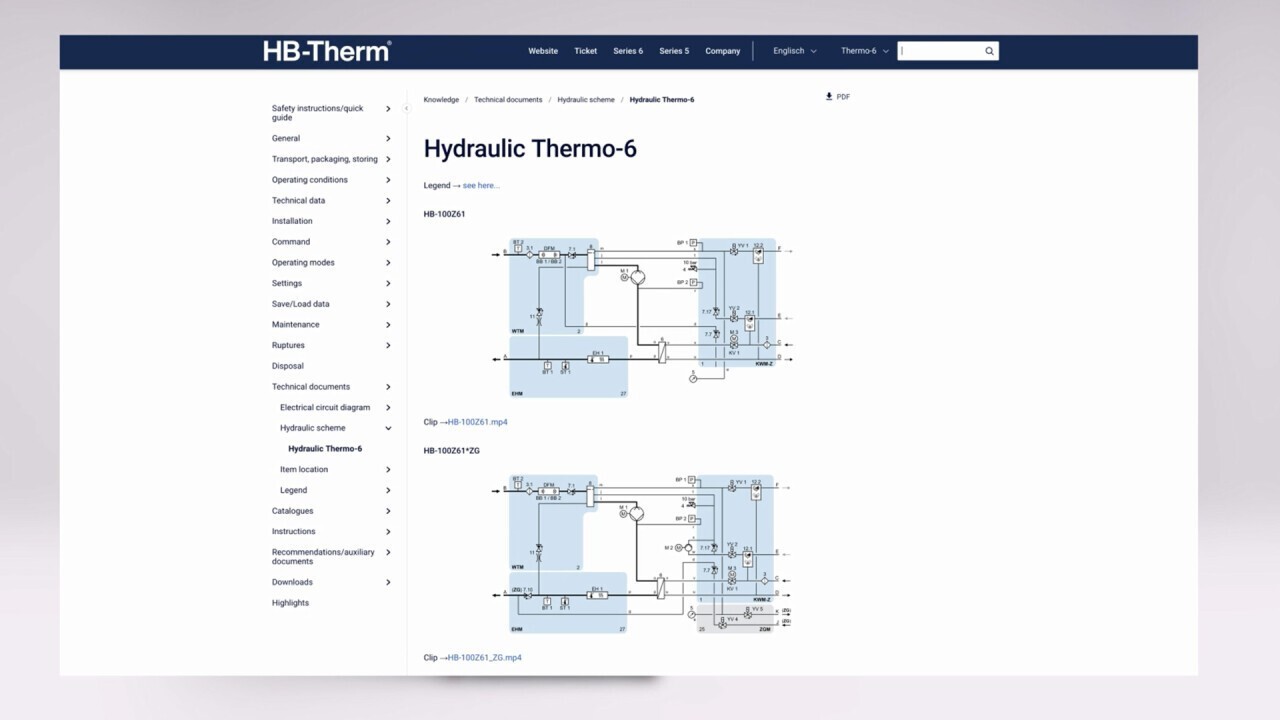

A lot of important knowledge: «Knowledge»

"Knowledge" provides all the information on operating and running the Series 6. The QR codes displayed on the control screen can be used with the "e-cockpit" app to call up the latest additional and background information on the relevant subject. On the PC, access is directly from the website and enables up-to-date and sustainable access to operating instructions and technical data from anywhere.

Comprehensive service management via «Ticket»

"Ticket", finally, is the new service management system for customers, through which all requests and events for all HB-Therm products are handled. In terms of global support, every end customer has access to "Ticket". The modern IT tool is designed for current and future requirements and grows with the needs of units and customers. Among others, the contents refer to unit-specific spare parts lists, calibration certificates as well as specific unit information.

Digitalization can also be simple: With HB-Therm!

Digitization no longer needs to frighten anyone if the start can be made as simply and safely as possible. In addition to the classic support, which remains fully available, HB-Therm gives every customer the opportunity for uncomplicated entry into the digital world of services. Having a clear overview of everything from anywhere, being able to control and analyze, and getting support exactly when it is needed is the great added value of digitalization as HB-Therm understands it. Being able to work together easily and securely - that's what HB-Therm has implemented on the new Series 6. Digitalization for everyone, intuitive and quickly usable in daily work.