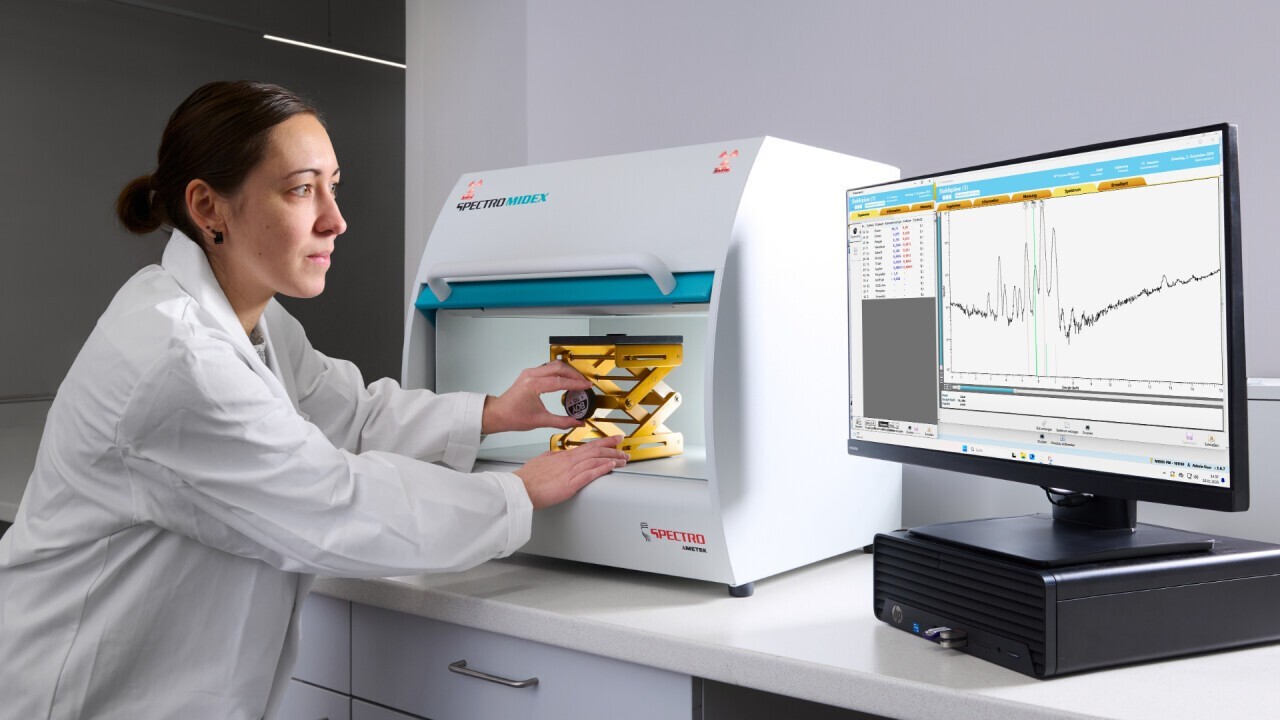

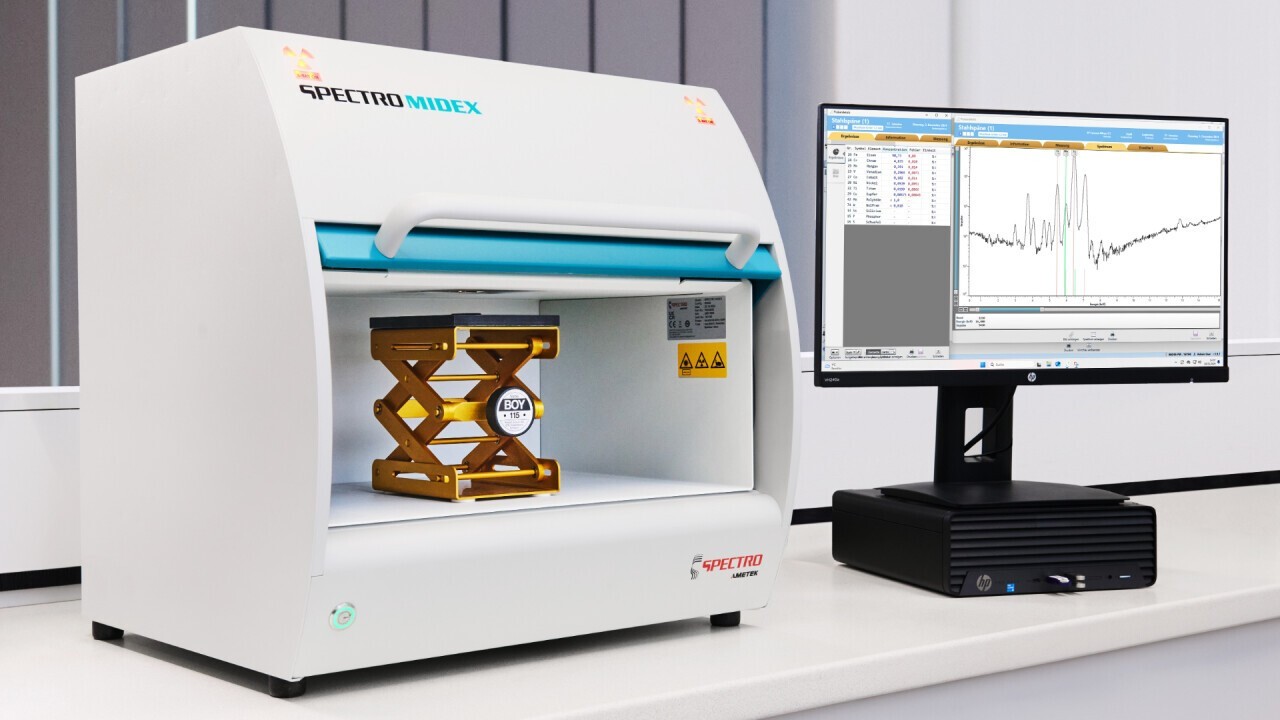

Non-destructive determination of the composition of materials and coating systems using X-ray fluorescence analysis

Using our XRF system, we can determine the chemical composition of materials and coating systems for you in a non-destructive manner. X-ray fluorescence analysis delivers results with exceptional sensitivity and analyzes the chemical composition of samples in the shortest possible time.

Characteristics of X-ray fluorescence analysis:

- Non-destructive analysis

- High precision and sensitivity

- Fast analysis times

- Determination of the alloy composition of the smallest components and metal chips

- Elemental analysis for coatings and the underlying base material

- Coating thickness analysis

- Analysis of contamination in electronic components and on printed circuit boards

- Harmful substance analysis in plastics

- Environmental analytics: analysis of harmful substances in soils and sediments

- Determination of the purity of precious metals

Applications for XRF at Quality Analysis

Environmental analytics:Analysis of soil samples, water samples, waste and recycling fractions to verify the presence of heavy metals such as lead, cadmium or arsenic.

Electronics manufacturing: Analysis of electronic components and printed circuit boards for contamination (e.g. heavy metals such as lead, cadmium and mercury) and analysis of the thickness of metallic coatings (e.g. layers of gold or nickel)

Precious metal analytics: From jewellery production to recycling in refineries, X-ray fluorescence analysis permits the cost-efficient and reliable analysis of purity.

Automotive: Checking the chemical composition of metals, plastics and coatings in various components for quality assurance.

Plastics analytics: Determination of the chemical composition of additives, filler materials or flame retardants in plastics and for the analysis of coatings on plastics

Your contact person