Digitalisation as the key to skills shortages and energy efficiency

The plastics industry faces a shortage of skilled labor and the need for energy efficiency. Digital technologies offer innovative solutions to streamline processes, conserve resources, and make companies future-ready.

Skilled labour shortage: support through digital assistance systems

The shortage of skilled labour affects numerous industries, and the plastics industry is no exception. Complex production processes such as injection moulding in particular require trained specialists - a resource that is becoming increasingly difficult to find.

Digital solutions and assistance systems from ENGEL offer valuable support here: they guide operators intuitively through complex processes, reduce dependence on expert knowledge and minimise sources of error.

One example is the set-up assistant, which supports operators when changing tools and optimising set-up times. With functions such as automatic mould recognition, step-by-step instructions and checklists, it ensures smooth processes - even for less experienced personnel.

Digitalisation is thus becoming a decisive lever for mitigating the shortage of skilled workers and remaining competitive in the long term.

Process optimisation through digitalisation: assistance systems as a success factor

ENGEL's digital assistance systems, such as iQ clamp control, iQ weight control or iQ flow control, make a decisive contribution to process stability and quality assurance. These systems are data-based and adapt dynamically to changing production conditions.

For example, iQ clamp control calculates and optimises the clamping force, of the machine, which not only reduces energy. iQ weight control automatically compensates for fluctuations in plastic viscosity and thus ensures consistently high product quality. These technologies make production processes more efficient and robust - and at the same time make the day-to-day work of the operating personnel easier.

Digital checklists in the machine control system standardise complex procedures such as set-up and production processes. They minimise errors, make training easier and increase efficiency - a clear advantage when dealing with a shortage of skilled workers. Standardised processes, supported by digitalisation, ensure productivity and quality, reduce the workload on personnel and make production future-proof.

Energy efficiency as a sustainability factor

Energy efficiency is a key objective of modern production processes. ENGEL shows that intelligent systems not only save time and money, but can also contribute to sustainability.

For example, iQ flow control enables energy savings of up to 60% in injection moulding temperature control. In addition, solutions such as ecobalance or ecograph plus offer precise monitoring and optimisation of energy consumption. As a result, companies not only benefit from lower operating costs, but also improve their environmental footprint.

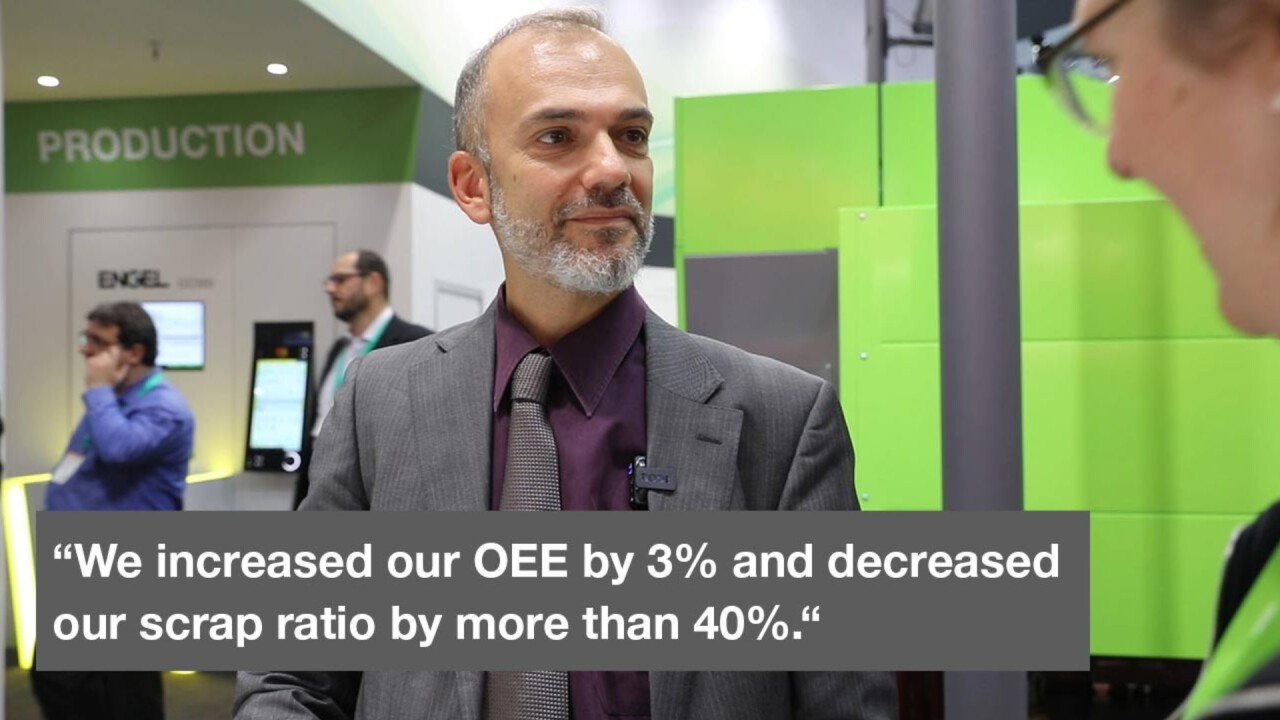

Digital assistants in practical use: 40% less rejects and 3% higher OEE - the impressive success story of BIC

As a world leader in the manufacturing of lighters, shavers and stationary products BIC operates more than 170 machines with over 190 tools at its production site in Athens, Greece.

As the number of installed machines grew, troubleshooting became increasingly difficult. To minimize long downtimes and to avoid high scrap rates, BIC has relied on our MES solution TIG authentig since 2013. In combination with the digital assistant systems iQ weight control and iQ process observer, BIC could increase their already high OEE by 3% and decrease the scrap rate by more than 40%.

Ioannis Voultzatis, Process & Mold Optimisation Manager at BIC, told us about his experience with digital solutions in injection moulding production: Watch the interview now

Conclusion: Digitalisation as a trailblazer for the future

Digitalisation offers the plastics industry enormous opportunities to address the shortage of skilled workers and energy efficiency in equal measure. Assistance systems and smart process optimisation tools not only make production processes more efficient and resource-saving, but also more user-friendly. This provides companies with the basis for remaining sustainable and competitive - even in a challenging market environment.

Are you struggling with similar challenges such as a shortage of skilled labour and increasing energy requirements? Let's find solutions together - with smart digitalisation and efficient processes: Start an enquiry!

Posted by

ENGEL

Frauenfeld, SwitzerlandYour contact person